ntroduction: Is Your Material Choice Inflating Costs and Undermining Competitiveness?

When sourcing safe and vault lock components internationally, the decision between zinc alloy die casting and traditional steel is far more than a technical specification—it directly impacts your final product cost, market competitiveness, and security performance. Many buyers fall into a trap: equating “heavier” with “more secure,” thus defaulting to steel. This often overlooks the chain reaction of soaring logistics fees, cumbersome installation, and unnecessary material waste.

This blog analyzes zinc alloy and steel from the perspective of an international procurement officer and product decision-maker. We will dissect the three critical dimensions of weight, total cost, and real-world security to help you make a data-driven, value-optimized sourcing decision.

The Core Pain Points: Three Major Challenges for Buyers

Before diving into the comparison, let’s identify the pain points you likely face:

-

Cost Pressure & Transparency Dilemma:

-

How do you balance raw material price with total manufacturing cost (including machining, finishing, assembly)?

-

How do volatile steel prices affect your product pricing and profit margin stability?

-

-

The “Hidden Cost” of Logistics & Operations:

-

How do heavy steel components silently consume your international shipping/air freight budget?

-

Does an overly heavy product lead to difficult installation for end-users, potentially hurting brand experience and increasing return rates?

-

-

Inherent Bias & Doubts About Security:

-

How do you evaluate a material’s true drill and tamper resistance, moving beyond just “feel”?

-

Can zinc alloy genuinely meet high-security standards (e.g., UL, EN)? Is it a sign of cutting corners?

-

Dimension 1: Weight Comparison – The Overwhelming Advantage of Zinc Alloy

Steel: Density ~7.85 g/cm³. A typical steel locking bolt or faceplate has significant weight.

Zinc Alloy (Zamak): Density ~6.6 g/cm³. Approximately 16% lighter than steel.

Direct Impact for Procurement:

-

Shipping Costs: International freight is charged by volume or weight (chargeable weight). Lighter zinc alloy components directly reduce cost-per-container. This saving becomes substantial in long-term, high-volume procurement.

-

Product Competitiveness: Modern safe design (e.g., home electronic safes, premium office cabinets) trends towards lightweight and portability. Lighter components help create more user-friendly products.

-

Installation Ease: Reducing final product weight simplifies installation, lowers labor costs, and improves end-user satisfaction.

Procurement Insight: Are you paying unnecessary freight for “excess weight” in your product? Is lightweighting a goal for your next-generation design?

Dimension 2: Total Cost Analysis – Looking Beyond Raw Material Price

| Cost Factor | Steel (Typical Process: Stamping/Machining) | Zinc Alloy (Typical Process: Die Casting) | Implication for the Buyer |

|---|---|---|---|

| Raw Material Price | Highly volatile, typically priced per ton. | More stable, with fixed alloy composition. | Zinc alloy offers more predictable costs, aiding long-term budgeting. |

| Processing Cost | High. Requires multiple stamping, cutting, drilling, tapping steps. High scrap rate, significant labor and machine time. | Very Low. Die casting is a single-step, net-shape process. Complex features (ribs, bosses, threads) can be integrated, minimizing secondary machining. | Zinc alloy drastically reduces per-part processing fees, especially for complex lock components. |

| Surface Finishing | Requires plating or coating for rust prevention. Demanding pre-treatment. | Naturally superior surface finish. Ideal for high-end PVD, plating, or painting with excellent adhesion and high yield. | Zinc alloy enables more aesthetic, durable finishes at a lower, more environmentally friendly processing cost. |

| Tooling Amortization | Stamping tooling cost is relatively low. | Die casting mold has a higher initial investment. | For projects with annual volumes above 10k-50k units, the mold cost is heavily amortized, making zinc alloy’s total per-part cost highly competitive. |

Key Takeaway:

For medium to high-volume safe lock components (e.g., handles, housings, dials, complex mechanisms), zinc alloy die casting typically offers a lower Total Cost of Ownership (TCO) than steel. The secret lies in shifting cost from the expensive, multi-step machining phase to a highly efficient, automated single-step forming process.

Procurement Insight: Are you only comparing raw material prices while overlooking more expensive machining and assembly costs? Is your order volume sufficient to leverage the economies of scale of die casting?

Dimension 3: Security Breakdown – Debunking the “Heavier is Stronger” Myth

Security is the soul of a safe lock. Here is an objective analysis based on engineering principles:

-

Drill & Tamper Resistance:

-

Steel: High hardness is an asset, but it has relatively lower toughness and can suffer brittle fracture under extreme impact.

-

Zinc Alloy: Modern, high-grade zinc alloys (e.g., Zamak 5, with added copper) offer an excellent combination of strength and toughness. Its yield strength resists attack from common tools, while its ductility absorbs impact energy, preventing catastrophic failure and causing drill bits to “skid,” increasing the difficulty of forced entry.

-

-

Structural Integrity:

-

Die casting allows for the design of complex internal reinforcing rib networks within zinc alloy parts. This dramatically increases the component’s rigidity and resistance to torsion without adding wall thickness or weight—a feat difficult to achieve with simple stamped steel.

-

-

Corrosion Resistance:

-

Steel is highly prone to rust, which weakens structure and hinders lock mechanics. It is entirely dependent on surface coatings.

-

Zinc alloy offers inherent resistance to atmospheric corrosion, providing an additional, reliable base layer of protection for security components.

-

-

Consistency & Reliability:

-

Die casting produces thousands of parts with exceptional dimensional consistency and material uniformity, ensuring stable, reliable security performance in every single unit. Stamped steel parts can vary due to tool wear and material batch differences.

-

Procurement Insight: True security stems from “intelligent design” and “fit-for-purpose material,” not just “massive weight.” Does your supplier offer design optimization expertise based on zinc alloy’s properties?

Decision Guide: When to Choose Zinc Alloy? When is Steel Still Needed?

Prioritize Zinc Alloy Die Casting when your component involves:

-

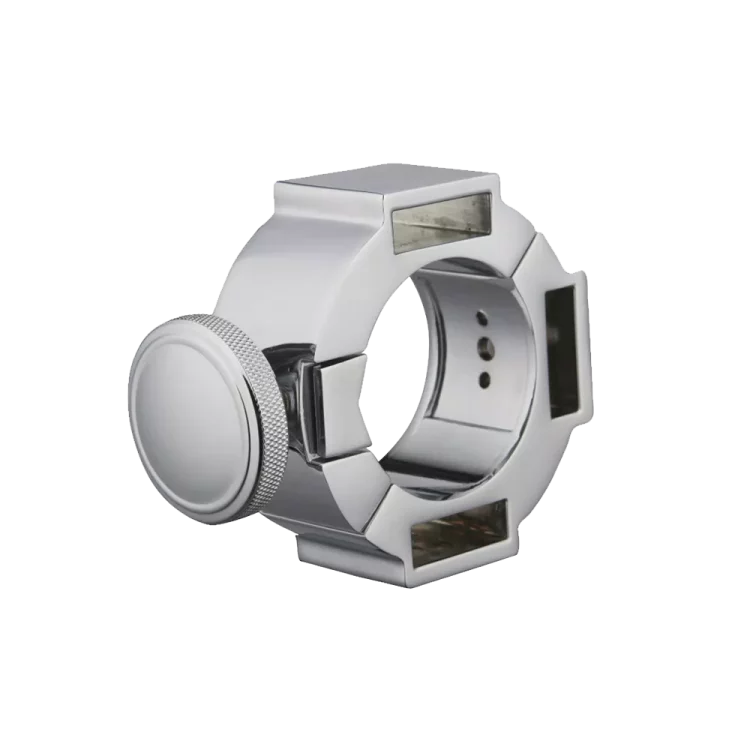

Complex 3D geometry (e.g., ornate handles, lock housings with integrated gears).

-

Medium to high-volume production (>10k units/year), seeking optimal TCO.

-

Weight-sensitive products requiring excellent surface finish and corrosion resistance.

-

Internal parts needing high rigidity in confined spaces.

Steel remains a valid choice when:

-

The part is an extremely simple flat plate or shaft (stamping cost is minimal).

-

It must withstand extreme, sustained point impact (e.g., certain military-grade scenarios).

-

Procurement volumes are very low, making die casting tooling investment unfeasible.

Conclusion: Towards a Smarter, More Competitive Sourcing Strategy

For most commercial and high-end residential safe lock components, zinc alloy die casting presents a highly competitive solution balancing weight, total cost, and engineered security. It can help you reduce total supply chain cost, address logistical challenges, and—through its superior manufacturability—empower product design innovation for safer, more aesthetic, and user-friendly end products.

As a specialist zinc alloy die casting solution provider, we partner with international brands and buyers like you to translate material science advantages into tangible market advantages for your products.

Your Next Step:

Are you exploring reliable, innovative component solutions for your next-generation safe or vault door lock? Download our free guide: “Design for Manufacturing & Cost Optimization for Zinc Alloy Lock Components” or contact our engineering team - STICK INDUSTRY directly for a dedicated cost-performance analysis of your upcoming project.